Protection of Businesses Act, 1978

Protection of Businesses Act, 1978

R 385

Mine Health and Safety Act, 1996 (Act No. 29 of 1996)RegulationsGuideline for a Mandatory Code of PracticeRisk-based Fatigue Management at MinesPart C: Format and Content of the Mandatory Code of Practice8. Aspects to be addressed in the Code of Practice8.2 Development of a fatigue management plan |

In general, the goal of a fatigue management plan is to maintain and, where possible, enhance safety, performance and productivity in operational settings, and manage the risk of fatigue in the workplace.

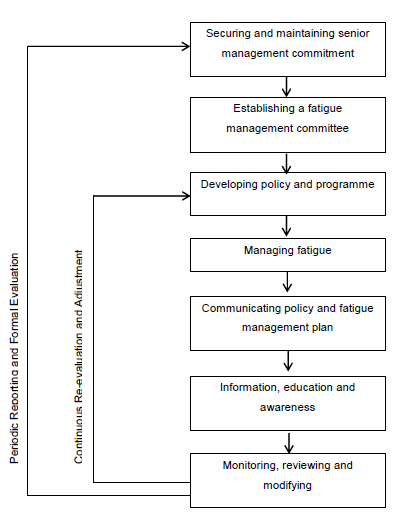

The recommended process of developing and maintaining a successful fatigue management plan consists of the following interrelated elements:

| (a) | Securing and maintaining senior management commitment; |

| (b) | Establishing a fatigue management committee; |

| (c) | Developing policy and programme; |

| (d) | Managing fatigue; |

| (e) | Communicating policy and fatigue management plan; |

| (f) | Information, education and communication; and |

| (g) | Monitoring, reviewing and modifying. |

Figure 1:

The fatigue management plan development process as a flow chart diagram

8.2.1 Management commitment and Stakeholder Buy-In

In order for a Fatigue Management Programme (FMP) to be effective, senior management must provide visible support, endorsement and allocate sufficient resources to establish, sustain, monitor and optimise the FMP.

8.2.1.1 Assign responsibility for the development of the FMP

Management should form a specific committee or assign responsibility to an existing high level Health and Safety Committee to establish and oversee the implementation the FMP. This should be a truly representative cross section of the mine's stakeholders; managers and union representatives (preferably health and safety representatives). Responsibilities, authority and accountability for managing fatigue within the FMP need to be defined. These roles and responsibilities include:

| • | Creating a statement of safety, performance, business goals and benefits the mine expects to achieve as a result of implementing the FMP; |

| • | Identifying and listing of the internal and external resources, support and expertise the mine will require to implement, monitor and improve the FMP; |

| • | Developing procedures for handling cases of employee fatigue; |

| • | Initialising protocols and objectives to evaluate the FMP. This can include comparative pre and post Key Performance Indicator (KPI) analysis and auditing of compliance; and |

| • | Planning, implementing and executing all facets of the FMP. |

| 8.2.2 | Establish a fatigue management committee |

Given the complexities involved in the design, implementation, monitoring and review of a FMP and the various different disciplines and department's involved close co-ordination and effective management are essential. The mine should establish a Fatigue Management Committee (FMC) at the mine to discuss and address the identified circumstances leading to fatigue and the control measures necessary. Action plans should be monitored at committee meetings.

The FMC should elect its own chairperson and scribe.

| 8.2.3 | Develop a policy (to be integrated into health policy) |

The FMC should develop the policy which should include:

| (a) | Statement of goals and objectives; |

| (b) | Clear roles, responsibilities and accountabilities for managing fatigue in the workplace; |

| (c) | Documentation of the support and expertise available to the programme; |

| (d) | Policies regarding employee alertness and fatigue, including possible disciplinary action for failure to maintain satisfactory levels of alertness on the job; and |

| (e) | Plan for reporting and reviewing organisational progress toward FMP goals. |

| 8.2.4 | Fatigue Risk Management |

In order for the mines to manage the risks of fatigue effectively and efficiently the following steps should be followed:

| Step 1: | Hazard identification; |

| Step 2: | Risk assessment; |

| Step 3: | Risk control; |

| Step 4: | Monitoring and evaluation; and |

| Step 5: | Documenting FMP. |

(Refer to Annexure A - C)

| 8.2.4.1 | STEP 1: Hazard identification |

| (a) | Identify factors that contribute to fatigue |

The first step when managing fatigue is to identify, and develop a list of all the factors that have the potential to contribute to fatigue within the workplace. Factors to consider are work time arrangements, type of work performed, work environment and non-work-related factors.

There are many ways of identifying workplace factors that contribute to fatigue. They include:

| (i) | Inspecting workplace rosters; |

| (ii) | Consulting with workers (ask them if they regularly feel fatigued and about any problems they have encountered, any near misses or unreported injuries); |

| (iii) | Consulting with workplace health and safety representatives and committees; |

| (iv) | Conducting a health and safety audit; and |

| (v) | Analysing injury and incident reports (pay particular attention to injuries and incidents that occur in periods of high fatigue, i.e. the latter half of shifts and night work, particularly between 2:00 and 6:00). |

| (b) | Identify the hazards of fatigue |

| (i) | Shift systems and rostering (See Annexure A); |

| (ii) | Ergonomics, environmental and work factors (See Annexure B); |

| (iii) | Personal factors (See Annexure C); |

| (iv) | Fatigue risk worksheets (see annexure D); and |

| (v) | Review accident or incident reports (See Annexure E). |

| 8.2.4.2 | STEP 2: Risk assessment |

| (a) | Assess the risks of fatigue |

Managing fatigue involves assessing the risks associated with the workplace factors that contribute to fatigue. For each of the risks:

• Determine the likelihood of an incident occurring at the workplace, bearing in mind the existing control measures;

• Determine the consequences of an incident occurring at the workplace, bearing in mind the existing control measures; and

• Combine the estimates of the likelihood and consequences to rate the risk.

Site-specific information and evidence of fatigue-related incidents could be used to assist in the risk assessment process. In this context review:

• Incident reports;

• Self-reports and complaints from employees;

• Reports from supervisors about any evidence of fatigue;

• Aggregate data from any EAP (ensure that confidentiality is maintained when using such data); and

• Environmental and medical monitoring and other advice from those with technical expertise in the relevant disciplines.

From this information, determine the risk factors that need to be controlled and prioritise actions.

| 8.2.4.3 | STEP 3: Risk Control |

Implement risk control measures

Control mechanisms should be put in place to manage the factors (identified through the risk assessment process) contributing to fatigue and to reduce the risks from employee fatigue.

The controls should address the sources of fatigue in the workplace and take into account the factors identified in the personal environment.

Control measures should be introduced using the hierarchy of controls. According to the hierarchy of controls, the ideal solution when managing fatigue is to completely eliminate factors that contribute to fatigue.

This may involve, for example, the elimination of night shifts and extended working hours. If possible, there are a number of control options that may be used alone, or in combination, to minimise and control exposure to fatigue:

These could include:

| (a) | Review and amendment of policies and procedures that are identified as having an effect on employee fatigue. |

| (b) | Adjustment of shift rosters to the most optimal, using the Bio-roster concept. The shift roster should take into account the need for the person to spend time with his/her family and participate in family and community affairs. The shift systems devised shall have the support of employees. |

| (c) | Elimination of unnecessary routine from the work schedule. |

| (d) | Control of the working environment to reduce factors that promote fatigue and drowsiness (e.g. physical workload, noise, vibration, temperature, lighting, etc.). |

| (e) | Lighting of rest areas to promote wakefulness and assist with adjustment of the circadian rhythm. |

| (f) | Suitable systems to monitor the performance of workers in safety- critical positions (e.g. drivers and operators) during the course of the shift and, where appropriate, suitable technology to monitor performance during the shift. |

| (g) | Regular medical examination and certification of fitness of employees and contractors in safety critical positions. Follow-up at suitable intervals on employees with chronic illnesses that may contribute to fatigue through the medical surveillance programme. Provision of education and information on how to best manage the condition to these employees by a suitable medical practitioner. |

| (h) | Availability of a suitable and easily accessible source of drinking water to all employees. |

| (i) | Designing meals that are provided on night shifts to reduce drowsiness and adverse health effects associated with eating at this time of day. |

| (j) | Substitute: introduce safer practices in place of those currently in use, e.g. increasing the length of breaks in a shift: |

| (k) | Engineer: introduce engineering controls, e.g. improve ventilation and illumination levels to improve alertness. |

| (l) | Administrative controls: introduce procedures and training programmes to support effective control of fatigue. |

| (m) | Personal protective equipment: carefully manage the use of protective gear as a control measure because it may not provide sufficient reductions in exposures, e.g. hearing protection devices may not provide sufficient attenuation over a 12-hour shift as opposed to an eight-hour shift. |

FATIGUE RISK MANAGEMENT TOOL

|

Hazard Identification |

Risk Assessment (Low – Moderate – Higher Risk: tick applicable box) |

Risk Control |

||

|

MENTAL AND PHYSICAL DEMAND OF WORK |

Low |

Moderate |

Higher Risk |

Interventions |

|

These include: |

||||

|

Monotonous work |

||||

|

Sustained physical or mental effort |

||||

|

Complex physical or mental tasks |

||||

|

WORK SCHEDULING AND PLANNING |

Low |

Moderate |

Higher Risk |

Interventions |

|

Length of shift |

||||

|

Sequential right shifts |

||||

|

Breaks during work |

||||

|

Breaks between work periods |

||||

|

EXCESSIVE COMMUTING TIMES |

Low |

Moderate |

Higher Risk |

Interventions |

|

WORK ENVIRONMENTAL CONDITIONS |

Low |

Moderate |

Higher Risk |

Interventions |

|

Exposure to hazardous substances |

||||

|

Exposure to extreme temperatures |

||||

|

Exposure to vibration |

||||

|

Exposure to noise |

||||

|

INDIVIDUAL AND NON-WORK FACTORS |

Low |

Moderate |

Higher Risk |

Interventions |

|

Sleep (amount and quality) |

||||

|

Chronic conditions |

||||

|

Alcohol and substance abuse |

||||

|

Fitness levels (BMI) |

||||

|

Nutrition |

||||

For ease of reference it is recommended that the fatigue risk management charts be used to list the identified hazards, the qualitative risk assessment and the interventions that have been put in place to mitigate the risk of fatigue.

| 8.2.4.4 | STEP 4: Evaluation |

Monitoring and Evaluation

The fatigue management plan should be reviewed at regular intervals to ensure that all relevant hazards are included and to assess the effectiveness of the controls. Some of the specific factors to consider as part of the monitoring and evaluation include:

| (a) | Have the control measures been implemented as planned?( |

| (b) | Are there any new operational processes that have been introduced? |

| (c) | Review available fitness, health, EAP and absenteeism data. |

| (d) | Review incident data. |

8.2.4.5 STEP 5: Documentation

Documenting fatigue management plan

The fourth step in the fatigue management process is to develop and document a plan detailing how control measures will be implemented. The fatigue management plan should be integrated as part of an overall occupational health and safety programme. The plan should be:

| (a) | Specific to the mine site. |

| (b) | Developed through consultation. |

| (c) | Publicly available, e.g. on display. |

| (d) | Communicated regularly and appropriately, e.g. in inductions and safety talks. |

| (e) | Regularly reviewed to take account of changes in site needs and knowledge about the risks. |

It should include:

| (a) | A statement of the principles for managing fatigue. |

| (b) | Roles and responsibilities of all levels of the organisation. |

| (c) | The risk assessments that have been undertaken. |

| (d) | The risk controls that are and will be in place, along with an implementation plan. |

| (e) | The support systems that already exist and that will be set up along with an implementation plan, e.g. EAP, training programmes and monitoring systems. |

8.2.5 Communicating the policy and fatigue management plan

Careful, but vigorous, communication is critical when 'rolling out' the fatigue management plan. Once the policy and the FMP framework have been adopted, they must be communicated to the entire workforce of the organisation. The communication framework should also provide and encourage opportunities for family members to be included in the information exchange.

Overall, the FMP will benefit from open lines of communication between all stakeholders, including employees, line supervisors, middle managers and senior management.

Providing information to families of employees can stimulate or reinforce the employees' willingness to focus attention on the important issue of fatigue.

| 8.2.6 | Information, education and awareness |

An appropriate information, education and awareness programme should be put in place to create awareness and educate all employees and their families on the impact of fatigue in the workplace, their role in managing the risks, and the controls in the workplace.

The programme should provide information and education on:

| • | The factors that cause fatigue. |

| • | The signs and symptoms of fatigue. |

| • | The risks of fatigue in the daily execution of their duties and the factors that cause fatigue. |

| • | The action they can take when feeling the effects of fatigue during their shift. |

| • | The impact of shift work, the importance of quality sleep and good nutrition to combat the effects of shift work. |

| • | How to maintain an environment that will allow good quality sleep. |

| 8.2.7 | Monitoring, reviewing and modifying |

The FMP should be subject to periodic assessments (minimum at least every two years) to ensure that it remains appropriate and effective, and can address existing and emerging or changed fatigue risks. Targets should be set for key parameters of the FMP. The review should cover the testing and auditing of all aspects of the FMP, in order to determine if controls are meeting business and safety goals.

The review should strike an appropriate balance between 'leading indicators' and outcome measures. The following are examples of the former:

| (a) | The number of individuals diagnosed and treated with sleeping disorders. |

| (b) | The number of individuals who self-report fatigue when at work. |

Obviously, attention should also be paid to outcomes and these will involve the usual measures such as:

| (a) | Incident/accident rates. |

| (b) | Near misses and safety-critical events. |

| (c) | Equipment damage. |

| (d) | Feedback from employees. |

| (e) | Absenteeism. |

| (f) | Staff turnover. |