Recognition of Customary Marriages Act, 1998

Recognition of Customary Marriages Act, 1998

R 385

Mine Health and Safety Act, 1996 (Act No. 29 of 1996)Guideline for a Mandatory Code of PracticeOccupational Health Programme on Thermal StressPart C: Format and Content of the Mandatory COP8. Key elements to be addressed in the COP |

Where the employer's risk assessment indicates a need to establish and maintain a system of occupational hygiene measurements and a system of medical surveillance, or where such systems are required by regulations, the aspects of the occupational health programme and the thermal stress management programme as set out in sections 8.1 and 8.2 below, must be addressed in the COP.

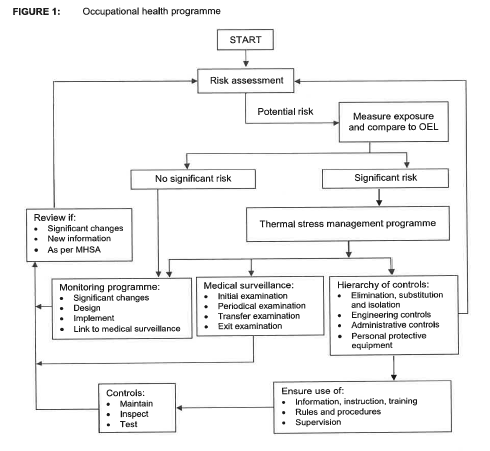

These key elements are shown in Figure 1: Occupational health programme below.

The occupational health programme to be implemented on the mine should be summarised in the COP in a flow chart similar to Figure 1: Occupational health programme. The occupational health programme has two components i.e. occupational hygiene and occupational medicine.

| 8.1 | Aspects of an occupational health programme |

| 8.1.1 | Risk assessment |

| 8.1.1.1 | The COP should set out measures to ensure that a qualitative and quantitative risk assessment process is followed, and takes into account all the factors influencing the health of employees. Where the available historical data is not sufficient to enable professional judgement, acceptable risk assessment methodologies should be used. |

| 8.1.1.2 | The risk assessment must be described with reference to: |

| (a) | The significant sources of thermal stress which would influence the environmental thermal load to which employees may be exposed, and which have been identified, in the activity area, such as: |

| • | Rock temperature due to geothermal gradient. |

| • | Machinery. |

| • | High humidity. |

| • | High radiant heat (see Annexure 3: Radiant temperature for information only). |

| • | Auto compression. |

| • | Rate of work (strenuous work). |

| • | Restricted and inclined work areas. |

| • | Ambient temperature. |

| • | Wind velocity. |

| • | Refrigerator rooms, etc. |

| (b) | Health effects associated with exposure to thermal stress (high environmental heat loads and radiant temperature). |

| (c) | The limits for each relevant parameter of the environmental thermal load on the mine e.g.: |

| (i) | WB in °C. |

| (ii) | DB in °C. |

| (iii) | Radiant temperature (GT) in °C. |

| (iv) | Velocity in metre per second (m/s) i.e. stoping and general ventilation. |

| (v) | Air volume per cubic metre per second per square metre (m3/s/m2) of the face (development end). |

| (vi) | Indices (DI, effective temperature, WBGT, etc.). |

| (vii) | WCET in °C. |

| (viii) | WBGT index. |

| (d) | The nature of the key workplace operations and activities that pose the greatest potential for exposure to thermal stress. |

| (e) | Occupations and the number of employees exposed to thermal stress. |

| (f) | The exposure pattern, i.e. intermittent and continuous. |

| (g) | The duration and frequency of employee exposure to heat stress. |

| (h) | The actual exposure levels measured compared to the OEL. |

| (i) | Control measures that are in place e.g. substitution, engineering controls, administrative controls, PPE etc. |

| (j) | The additional control measures required to be instituted in order to reduce or maintain exposures to below the OELs. |

| (k) | The frequency of any ongoing monitoring to assess the effectiveness of the controls mentioned above. |

Note:

For the purpose of the risk assessment, the commodity codes, activity codes and occupat8ional codes as set out in Annexure 1 (Mandatory codes list) should be used.

| 8.1.1.3 | The COP must indicate the type(s) of risk assessment to be undertaken for thermal stress monitoring considering the following: |

| (a) | Baseline risk assessment. |

| (b) | Issue-based risk assessment. |

| (c) | Continuous risk assessment. |

Note:

Chapter 3 of the handbook published by the SIMRAC, "Handbook on occupational health practice in the South African mining industry", may be consulted and any other methodology to assist in conducting a risk assessment.

| 8.1.1.4 | Review of risk assessment |

The COP must address the review of the risk assessment annually (based on the thermal stress monitoring data of the previous cycle) and whenever there is change at the mine that could have an impact on the original assessments, and/or at least in the following instances:

| (a) | Outcomes of medical surveillance programmes indicate the need for it. |

| (b) | A MHSA section 11(5) investigation indicates the need for it. |

| (c) | The introduction of new or revised legislation. |

| (d) | The introduction of new mining methods. |

| (e) | Process changes are introduced (e.g. in process plants). |

| (f) | The introduction of new types of machinery. |

| (g) | The modification of current machinery affecting the heat load and operation. |

| 8.1.2 | Parameters for the identification of thermal stress risk |

The employer must apply the following parameters to identify thermal stress risks.

| 8.1.2.1 | Non-significant risk |

| (a) | WB < 25.0°C and |

| (b) | DB < 32.0°C and/or |

| (c) | GT < 32.0°C and/or |

| (d) | WBGT index < 25.0°C . |

| (e) | WCET ≥ 10.0°C should be applied to define a non-significant cold risk. |

| 8.1.2.2 | Significant risk |

| (a) | WB ≥ 25.0°C - < 27.5°C |

| (b) | DB ≥ 32.0°C - < 37.0°C |

| (c) | GT ≥ 32.0°C - < 37.0°C |

| (d) | WBGT index ≥ 25 - < 30° determined over a period of one hour |

| (e) | WCET < 10.0°C should be applied to define a significant cold risk. |

| 8.2 | Thermal stress management |

| 8.2.1 | Non-significant risk |

A monitoring programme is not required, but the employer must keep a portfolio of evidence.

| 8.2.2 | Significant risk |

The COP should put measures in place to ensure that a thermal stress management programme is established and maintained for all workplaces with a significant risk.

The thermal stress management programme should address the following aspects:

| (a) | The thermal stress management structure (see section 8.2.2.1). |

| (b) | Risk assessment (see section 8.2.2.2). |

| (c) | The determination of thermal environments (see section 8.2.2.3). |

| (d) | The thermal stress monitoring strategy (see section 8.2.2.4) |

| (e) | Quality control (see section 8.2.2.5). |

| (f) | Hierarchy of controls (see section 8.2.2.6). |

| (g) | HSM (see section 8.2.2. 7). |

| (h) | CSM (see section 8.2.2.8). |

| (i) | Medical surveillance programmes (see section 8.2.2.9). |

| (j) | Fitness to perform work (see section 8.2.2.10). |

| (k) | Immediate incident management (see section 8.2.2.11). |

| (l) | Reporting and recording (see section 8.2.2. 12). |

The COP must address the following points.

| 8.2.2.1 | Thermal stress management structure |

The COP must make provisions for the employer to put measures in place for the establishment of a thermal stress management committee whose members are appointed in writing, and have defined roles, responsibilities and authority to manage thermal stress, including but not limited to the following:

| (a) | Employer designated representative as the chairperson. |

| (b) | A MHSA section 12(1) appointee. |

| (c) | An engineer as contemplated in regulation 2.13.1 of the MHSA (for the purpose of thermal stress control). |

| (d) | OMP. |

| (e) | Human Resource representative. |

| (f) | Human Resource Development representative (education and training). |

| (g) | Full-time health an safety representatives. |

| 8.2.2.2 | Risk assessment |

The outcomes of the risk assessment as in section 8.1.1 above will be utilised as inputs into the thermal stress management programme.

NOTE:

Where the available historical data is insufficient to enable a professional judgement regarding the extent of any risk, acceptable methodologies for the identification or the determination of thermal stress should be used.

| 8.2.2.3 | Determination of thermal environments |

The employer must identify the thermal environment as per the following:

Step 1

The sub-division of the mine into measurement areas e.g.:

| • | Measurement area 1 = surface. |

| • | Measurement area 2 = underground section A. |

| • | Measurement area 3 = underground section B. |

| • | Measurement area 4 = underground section C etc. |

NOTE:

Surface operations proceed to step 3.

Underground operations proceed to step 2

Step 2

Measurement areas for underground mines should be sub-divided into ventilation districts.

NOTE:

In order for an area to be classified as a ventilation district it:

| 1. | Must be ventilated independently from other areas. |

| 2. | Must have independent intake and return airways. |

| 3. | Does not contaminate other areas |

Step 3

Measurement areas for surface operations must be sub-divided into activity areas as per the activity area code list found in Annexure 1: Mandatory codes list.

Ventilation districts must be sub-divided into activity areas as per the activity area code list found in Annexure 1: Mandatory codes list.

Step 4

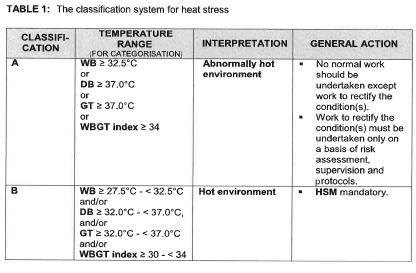

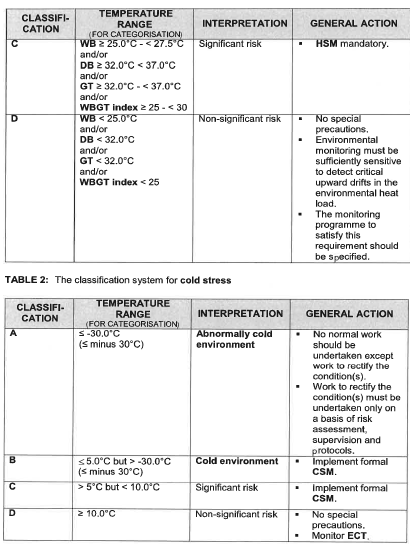

The employer must categorise (as per Table 1: The classification system for heat stress and Table 2: The classification system for cold stress below) the activity areas based on the historical thermal environmental data.

Step 5

Conduct a statistical analysis to ensure that thermal environments are correctly classified. The results of the thermal environmental parameters (as per Table 1: The classification system for heat stress and Table 2: The classification system for cold stress below) used, from either historical data or measured data should be compared to the respective OEL/standard.

Step 6

Once the thermal environmental parameters (as per Table 1: The classification system for heat stress and Table 2: The classification system for cold stress below) within each activity area have been compared to the respective OEL/standard, each activity area can now be categorised into classification bands. For classification purposes, use the 90th percentile value for heat stress (the classification for heat stress should be based on the worst measured parameter) and the 10th percentile value for cold stress.

NOTE:

The employer must ensure that in defining any thermal environment, the precautions listed below are heeded to:

| • | Care should be exercised to detect trends where the thermal environment changes, especially from 'cool' to 'hot', or from 'hot' to 'abnormally hot'. |

| • | Regular monitoring is clearly indicated, even if only on a random basis, and 'cool' environments should not be excluded, especially when marginal |

| • | The specific protocol would be dictated by prevailing circumstances, and therefore cannot be stipulated or prescribed. |

| • | Seasonal drifts could be crucial and to rely on winter temperatures may lead to an underestimation of the risk and vice versa. Environmental monitoring should consider this. |

NOTE:

| • | Using mean values for the purpose of categorisation may underestimate the risk if a significant number of exposed employees have to enter environments close to, or at the upper end of the range of recorded values. |

The classification bands for a thermal environment are tabled below and these tables form part of this guideline and must be complied with—

Step 7

Reclassification of thermal environments should be considered when any of the following events occurs:

| (a) | Exposure levels change due to controls being initiated, and likewise, when controls deteriorate. |

| (b) | Employee complaints are received. |

| (c) | Processes are changed (e.g. change in procedures, mining and ventilation layouts, mining methods, plant, equipment or material). |

| (d) | Occupational illness related to the thermal environment occurs. |

| (e) | Change in exposure category occurs. |

| (f) | Other events warranting re-evaluation e.g. new regulatory initiatives. |

NOTE:

| • | The previous cycle for surface operations refers to the data from a similar monitoring period for the previous year. |

| • | The previous cycle for underground operations refers to the data from the previous quarter. |

| 8.2.2.4 | Thermal stress monitoring strategy |

The employer must implement a thermal stress monitoring strategy and clearly describe the following in the COP:

| (a) | Identify internationally or nationally acceptable measurement methodology used for thermal stress monitoring. |

| (b) | Describe the acceptable measurement methodology used for thermal stress monitoring. |

| (c) | The record keeping system used by the mine to record the thermal stress data. |

| (d) | The instrument(s) used to assess thermal stress (heat and cold). |

| (e) | The frequency of maintenance and the calibration of measuring instruments. |

| (f) | The monitoring period for heat and cold stress must be determined by the risk assessment and the identified thermal stress measurement methodology. |

NOTE:

| • | Thermal monitoring for heat stress is to be conducted on an annual basis during the warmest period of the year, and cold stress during the coldest period of the year, as determined by the risk assessment. |

| • | Care should be exercised to detect trends in the thermal environment changes, especially from 'cool' to 'cold'. |

| • | Regular monitoring is clearly indicated, even if only on a random basis, and 'cool' environments should not be excluded, especially when marginal |

| • | The specific protocol would be dictated by prevailing circumstances, and therefore cannot be stipulated or prescribed. |

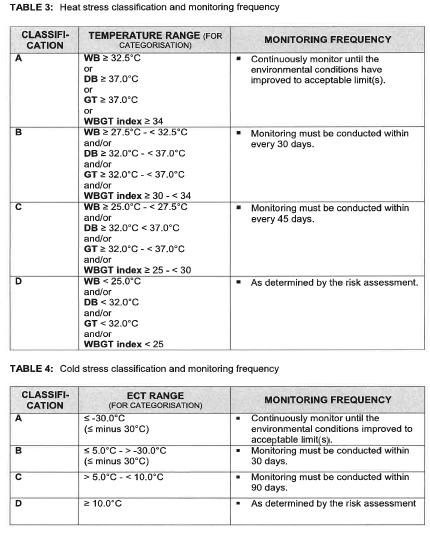

| (g) | Monitoring frequency |

The monitoring frequency must be defined in the COP as per Table 3: Heat stress classification and monitoring frequency and Table 4: Cold stress classification and monitoring frequency below or as determined by the risk assessment, whichever is the higher standard.

| (h) | Monitoring programme |

In developing the monitoring programme the following shoudl be considered:

| (i) | Routine monitoring |

All working places should be monitored in terms of the most relevant parameter of the prevailing thermal environment (e.g. WB, DB and velocity) that is periodically done as per the monitoring frequency.

| (ii) | Adjusted monitoring |

Where prevailing conditions are closer to the upper limits of the category or where trends are discernible, the frequency of monitoring must be increased in accordance to the risk in order to manage the risk on a day-to-day basis.

| 8.2.2.5 | Quality control |

The COP must describe a quality control programme taking into account, but not limited to, the following:

| (a) | Maintenance and calibration of instruments used for thermal stress monitoring. |

| (b) | Measurement methods to assess thermal stress. |

| (c) | HTS. |

| (d) | Competency of people assessing thermal stress. |

| (e) | Reporting on thermal stress conditions and measurements. |

| 8.2.2.6 | Hierarchy of controls |

The COP should address the hierarchy of controls, which are going to be implemented to "mitigate the risk of exposure to thermal stress". The following hierachy of controls should be taken into consideration:

| (a) | Elimination. |

| (b) | Substitution and isolation. |

| (c) | Engineering controls. |

| (d) | Administrative controls. |

| (e) | PPE. |

| 8.2.2.7 | HSM |

HSM must be implemented by the employer where the risk assessment determines a significant risk. The following aspects must be addressed in the thermal stress COP and where applicable, cross-reference to the standard operating procedures of the mine:

| (a) | Medical or physical examinations (see Annexure 6: Medical/physical examinations). |

| (b) | HTS (see Annexure7: Heat tolerance screening). |

| (c) | Work practices for surface, opencast and underground operations (see Annexure 8: Work practices: Surface, opencast and underground operations). |

| (d) | Absenteeism from routine work in hot environments (see Annexure 9: Absenteeism from routine work in hot environments). |

| (e) | Water and nutritional requirements during work in heat (see Annexure 10: Water and nutritional requirements during work in heat). |

| (f) | Emergency work in abnormally hot environments - underground (see Annexure 11: Emergency work in abnormally hot environments - underground). |

| 8.2.2.8 | CSM |

The COP requires a CSM programme to be implemented where the risk assessment determines a significant risk.

The following points must be addressed in the CSM programme:

| (a) | Medical or physical examinations. |

| (b) | Safe work practices and supervision (strategy for dealing with cold environments). |

| (c) | Precautions to prevent cold stress e.g. PPE. |

| (d) | Emergency work. |

Note:

Annexure 4: Cold stress management should be consulted when drawing up the CSM programme.

| 8.2.2.9 | Medical surveillance programme |

The COP must address the following points:

| 8.2.2.9.1 | The medical surveillance programme as it relates to thermal stress must be described in the COP (see Annexure 6:Medical/physical examination). |

| 8.2.2.9.2 | The method used to link the thermal stress exposure measurements to the employee's records of medical surveillance as required in terms of section 12(3) of the MHSA, must be described in the COP. |

Note:

| • | A manual or computerised system could be utilised to link this information. |

| • | These systems may have to be customised in accordance with the operations specific needs. |

| • | Effective communication between the 12(1) appointee of the MHSA and the OMP is required to ensure that linking employees' exposure history and medical surveillance information is meaningful. |

| 8.2.2.9.3 | A procedure must be described in the COP on how the thermal stress medical surveillance (initial, periodic and exit examinations) will be conducted. The medical surveillance done must exclude the presence of any abnormality that may compromise physical work in thermal environments. This must include, but is not limited to, the following: |

| (a) | The general medical examination: |

| (i) | History (occupational, medical, family and social) and thermal related disorders (cramps, exhaustion, stroke and hypothermia) must be obtained. |

| (ii) | Urinalysis must be done to exclude the presence of haematuria, proteinuria and glycosuria. |

| (iii) | The examination must be done to exclude any presence of jaundice, anaemia, cyanosis, clubbing, oedema, abnormal lymph nodes and febrile disease. |

| (iv) | The blood pressure must be checked and if uncontrolled hypertension (>160/95) and gross cardiovascular abnormalities are present, these require a full investigation and obtaining a specialist opinion regarding the fitness for physically demanding work in a hot environment. |

| (v) | A skin examination must be done to determine that it is intact with no infections such as advanced athlete's foot, cellulitis, scabies, etc. |

| (vi) | A cardio-respiratory examination including a chest x-ray and spirometry, must be done to exclude any abnormalities. |

| (vii) | Ear, nose and throat examinations must be done to exclude inflammation or infection (tonsillitis, pharyngitis, chronic suppurative otitis media, etc.). |

| (viii) | An abdominal examination must be performed to exclude the presence of organomegaly or hernias. |

| (ix) | A screening neurological examination must be done to exclude any gross abnormalities. |

| (b) | Physical evaluation |

The following physical evaluation must be performed to assess the medical and physical fitness of an individual to undergo HTS (see Annexure 6: Medical/physical examinations).

| (i) | Age |

| (ii) | General physical appearance. |

| (iii) | Body dimensions |

| 8.2.2.9.4 | Methodological standards for test techniques forming part of medical surveillance. |

| 8.2.2.9.5 | The methodology used to comply with the legal requirements in respect of medical surveillance for thermal stress as contemplated in section 13(2) of the MHSA, must be described in the COP. |

| 8.2.2.9.6 | The employer must ensure that for routine work, the anticipated work environment takes into cognisance the categories A, B, C and D as referenced in section 8.2.3.3 above, Table 1: The classification system for heat stress and Table 2: The classification system for cold stress, to assist the OMP in making an informed decision in terms of fitness to work. |

| 8.2.2.9.7 | The COP must provide that the employer make the thermal environmental classification available to the OMP for medical surveillance.. |

| 8.2.2.9.8 | Heat (heat cramps, heat exhaustion and heat stroke) and cold disorders (frostbite and hypothermia) can occur and do occur in thermal environments. Whenever such incidents occur, immediate and full investigations should take place with the primary purpose being to: |

| (a) | Prevent the recurrence of such incidents and by collating such data. |

| (b) | Provide input to HSM or CSM programme reviews (for clinical signs and symptoms of heat-related illnesses refer to Annexure 12: Addendum for the thermal stress guideline on the criteria for heat-related illnesses). |

| 8.2.2.9.9 | A procedure where work in abnormally hot and cold environments is to be undertaken must be developed. Any adverse consequences, as a result of such exposures, should be entered in the medical surveillance record of employees (see Annexure 11: Emergency work in abnormally hot environments). |

| 8.2.2.10 | Fitness to perform work |

The employer must develop and implement a HTS procedure to monitor employees, taking into consideration the following (see Annexure 7: Heat tolerance screening):

| (a) | Fitness of employees to work should be based on the individual's merits. If, however, an employee who has been working in a hot environment for years without any manifestation of heat related illness; fails HTS, further assessment should be done to exclude any other medical condition(s) that may render the employee unfit to work in a hot environment. Such an employee may not be declared medical incapacitated based on the failure of HTS only, but a holistic approach needs to be undertaken to determine fitness to continue with work in a hot environment. If, however, the same employee is transferred to a hotter environment a risk-based medical surveillance will be conducted. |

| (b) | The medical and work history of the employee prior to finalising fitness to work in a hot environment. |

| (c) | HTS failure does not automatically translate to incapacity or unfitness to work in a hot environment unless there is a proven underlying medical condition. |

| 8.2.2.11 | Immediate incident management |

Whenever there is an unexplained incident of an employee collapsing whilst working in an abnormally hot environment, such incident should be treated as a possible case of heatstroke.

The core body temperature should be taken and there must be rapid cooling of the affected employee as suggested in Annexure 12: Addendum for the thermal stress guideline on the criteria for heat-related illnesses (heat exhaustion and heat stroke).

| 8.2.2.12 | Reporting and recording |

The COP must address the following:

| (a) | Reporting on a quarterly basis for all classifications, that is A, B and C (refer to Annexure 2: Mandatory occupational hygiene thermal stress reporting forms). |

| (b) | A record keeping system, which records the exposure history of each thermal environment at the mine and any other thermal stress monitoring records e.g. calibration certificates, sampling sheets, etc. This should be kept and be readily available at the mine, including any reasons for deviation on sample results such as: |

| (i) | Controls not operating effectively. |

| (ii) | Events or factors which influenced the results, e.g. excessive wind speeds, etc. |

| (c) | Occupational hygiene measurement records linked to the medical surveillance records, must be kept by the employer. |

| (d) | Quarterly re-classification that must be conducted if results are proven and consistent. |

| (e) | Any incident of unconsciousness and incapacitation from heatstroke or heat exhaustion must be reported to the DMRE as stated in chapter 23 of the MHSA regulations. |

Historical data is to be maintained as provided for in section 15(2)(a) and (b) of the MHSA.